My semester research project was taking a look into what is natural air ventilation and how it is used. I simply define natural air ventilation as simply just bringing outside air into the building. However wiki would define it out more as “natural ventilation is the process of supplying and removing air through an indoor space without using mechanical systems…wind-driven ventilation and buoyancy-driven ventilation.” The two systems mentioned from wiki have two key ways to design for this ventilation:

- Wind-driven ventilation: is based on the amount of wind going through the building, if there is too much wind in the space could cause a wind-tunnel effect and would not be pleasant for the users.

- Bouyancy-driven ventilation: is the air density difference between indoor to outdoor air or differences between rooms. This follows the concept of hot air rises and cool air falls due to the density. Stack effect or the chimney effect is used to achieve this system.

The paper also looked into ASHRAE 55 Standard: Thermal Environment Conditions for Human Occupancy to see how they define natural ventilation. This standard is a base line and gives guidelines to how base thermal comfort in spaces, but there is a few undefined areas that could leave designers confused. Listed are a few key points.

- Does not take into account specific locations

- User’s response to their environments (age, health, activities, gender)

- Thermal comfort based on a 80% acceptable, 20% dissatisfaction based from Predicted Mean Vote (PMV) and Predicted Percentage Dissatisfied (PPD)

- Urban conditions (pollution, security)

- If you use any mechanical system, then you do not have natural ventilation

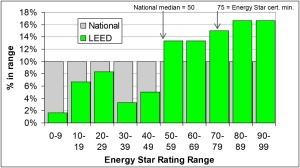

I searched for two case studies in the Chicago region to show the diversity of using natural ventilation with mechanical “hybrid” systems. Both are set in private universities and have similar square footage, programs, and only a year apart, but you can see with money, a proper design team, and support can develop these integrated systems. Since the perfect conditions for acceptable natural air ventilation only happen 50-60 days out of the year, the use of mechanical system to help support the natural ventilation in the off periods ,winter and summer months, is needed.

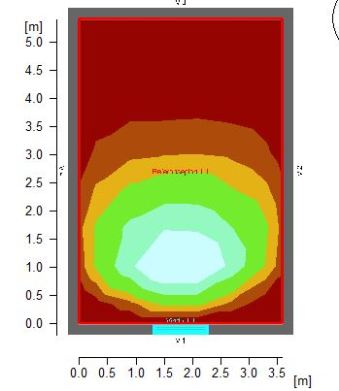

Case Study I: Harm A. Weber Academic Center at Judson University in Elgin, IL (4 story, 88,000sf). The Academic Center opened in 2007 and is one of the first in the region, especially in Chicago.

Design methods:

- Central lightwell acts like the stack/chimney effect

- Night Flushing

- Integrated Photo-voltaic (PV)

- Thermal Massing

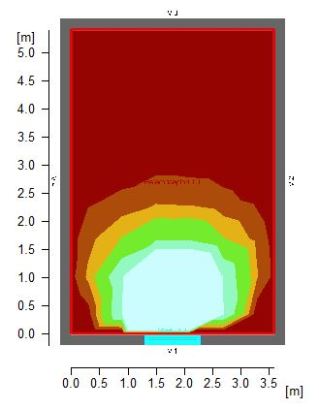

Case Study II: Richard J. Klarcheck Information Commons at Loyola University (north side campus) in Chicago, IL (4 story, 70,000sf). Opened in 2008 had one key goal in mind for this new building, a transparent effect to be able to see Lake Michigan.

Design methods:

- Double-Skin Façade (west wall for the stack effect)

- Night Flushing

- Radiant ceiling (for cooling)

- Thermal Massing

- Automated shading system

There is no wrong or right answer when it comes to natural air ventilation when it comes to the guidelines engineers have. This is not a new technology and is climate and urban sensitive on locations. When it comes to challenging standards or pushing the limits, there must be a good team (architects, multi-field engineers, stakeholders, etc.) to develop the proper combination of systems for the building. After a couple of years if the building is not performing to expectation there needs to be flexibility to the design since a lot of estimation/trial and error occur when dealing with natural air ventilation.

Sources:

[1] http://www.shalesmcnutt.com/projects/education/judson-university-harm-a-weber-academic-center/

[2] Kaiser, Keelan P., and David M. Ogoli, Ph.D, (2010) “The Harm A. Weber Academic Center

and the Greening of Judson University.” Judson University, 1-12.

[3] Image from author

[4] District Energy by Elara

[1]

[1] [2]

[2] [3]

[3] [4]

[4]

You must be logged in to post a comment.