Shading element is one of the important components of the skin façade and the effectiveness of the building enclosure depends on the shading configuration of the entire system. However, the shading system increases the cost of the construction and maintenance; and in case of double skin façade it requires a wide cavity in order to contain the blades and a space for cleaning and maintaining these devices that make the Architects very careful before making a decision on using the shading in their design. One of the purpose of the double skin facade is to provide a shell for the shading elements especially in the high rise buildings where the wind add a significant load on the shading system otherwise a sturdy structure to protect the system should be used in case of using the single skin façade.

The traditional assumption that the facade should be static with rigid walls or curtain wall is no longer valid, the homeostatic facade examines the possibility of using a responsive system to the environment. With the emergence of smart shading, an interest in using creative building systems and the need to build durable double skin facade with dynamic elements, the building enclosure can be more sensitive to the environment.

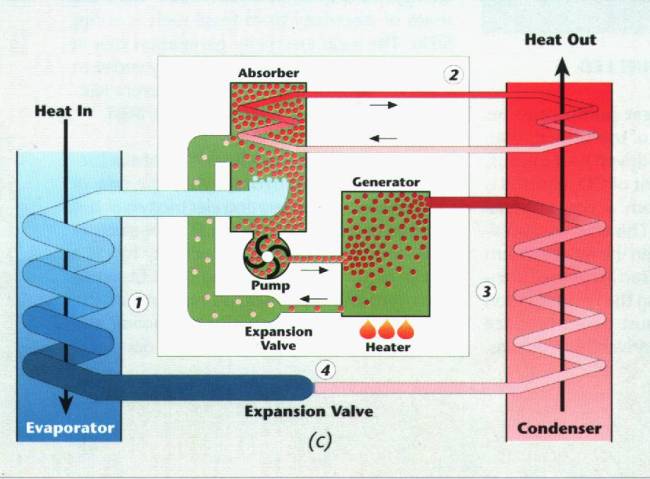

Using Shape Memory Alloy as blinds is one of the ideas to create a shading system that react automatically with the temperature variance without the need of any mechanical equipment or power of any kind and the vent ratio and air flow is determined by the properties of the material. Each blind is composed of two separate layers of different metal joined together which expand at different rates as they are heated. Therefore, when they are heated one reacts more quickly and bends in one direction, then when they cool down they go back to their original position. Bimetal is commonly used today in thermostats as a measurement and control system and in electrical controls as a component in mechanical systems therefore instead of using it as sensor that regulates the blinds opening why they cannot become the shading element itself. Nevertheless, we are talking about flexible and very thin strips, compared with the typical blinds that have firm structural frames. Therefore, using the bimetal blinds on the exterior face of the building façade make them vulnerable to the outside conditions. As a result we cannot think of this system without integrating it into a double skin facade.

Smart shading has many areas that can be developed depending on combining different technologies to achieve the goal of built an efficient building enclosure. New materials and different configurations can be tested that lead to alternative connection details. Bimetal applications on the building façade and the DSF are both serve to create an interactive façade with the temperature changes as wells as the direction of the sunlight and since the external solar protections are more effective than internal shading devices. In the case of the double-skin facade, the bimetal sheets can be integrated in the cavity. It is thus protected from the bad weather and pollution. Solar protection can remain in place even in the event of important wind, which represents an undeniable advantage for DSF of the high rise buildings.

In the last years, more public interest in sustainable design, energy conservation and zero-emission building design has provoked the designers to find alternative solutions. With the revelation of new smart materials, the evolution of digital technologies and the availability of mass-customization methods, Reacting with outside temperatures, has the potential to develop self-actuating intake or exhaust for facades.

You must be logged in to post a comment.